Varem has carried out a series of tests in its laboratories to test the operation of its vessels for pumping systems and compare them with other products on the market.

In particular, it carried out a series of parallel tests on vessels with balloon membrane and with diaphragm membrane, which offered proof of the significant superiority of the first solution, used by Varem, in given conditions and also drew attention to the limitations of the second solution.

|

Membrane Vessel |

Diaphragm Vessel |

|

|

The test carried out was the EN13831 cycle test indicated in the Directive PED 97/23/EC, which provides for correct operation of the product for 50,000 cycles at an average temperature of 30°C.

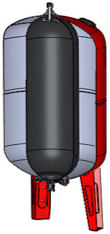

Naturally, one of the most important aspects for determining correct operation of an expansion vessel is the complete discharge of the water contained, for the whole duration of the test. Therefore, we carried out the tests also paying close attention to this aspect, monitoring the performances of the two products being compared in two situations: with pump shut down at 3 bar and at 5 bar.

Case 1: shut down pressure of 3 bar

|

|

At a pump shut down pressure of 3 bar, the expansion vessel is filled with a usable volume of water equivalent to 25% of the nominal value. By way of example, a tank with a nominal value of 100 l contains 25 l of water. In this configuration, comparison between the two types of tank showed that the test was passed without any problem. |

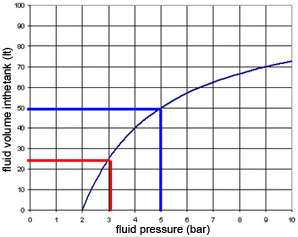

Case 2: shut down pressure of 5 bar

|

|

At a pump shut down pressure of 5 bar, the expansion vessel is filled with a usable volume of water equivalent to 50% of the nominal value. By way of example, a tank with a nominal value of 100 l contains 50 l of water. In this configuration, comparison between the two types of tank showed a significant reduction in the discharge capacity of the diaphragm vessel, which starting from 4000 cycles was measured as 20%. In the case of the 100 l tank, the usable volume of water discharged decreased from the 50 l expected to 40 l. |

Analysis of the tanks at the end of the 50,000 test cycles brought to light the reasons for this abnormal reaction of the diaphragm vessel.

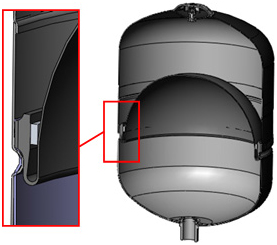

The solution with shut down pressure of 5 bar caused yielding of the diaphragm membrane in the fastening area, as shown in the images below:

In fact, this area is subjected to increased stress as the pressure inside the vessel increases, contrary to membrane vessels in which the pressure is spread evenly over the whole of the surface of the membrane.

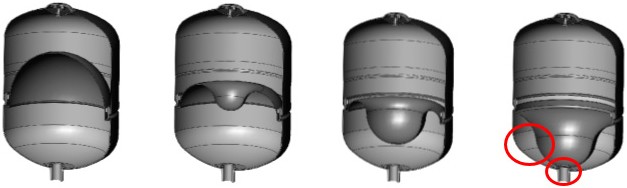

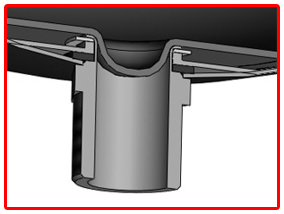

As a direct consequence of this, the diaphragm behaves abnormally, as indicated in the sequence of images below:

The rubber stretches until it blocks the water inlet/outlet before adhering fully to the inner walls of the vessel, retaining 20% of the usable volume of water inside the vessel.

This situation creates two negative consequences for operation of the system:

Therefore, we conclude that in systems with pressures in excess of 3 bar, the use of membrane vessels is highly recommended.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Available s/s flange and |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Available stailess steel flange and |

|

Water Line WATER LINE HORIZONTAL

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

* Available version with s/s flange and |

|

Water Line WATER LINE VERTICAL / HIGH PRESSURE

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Available version with s/s flange |

| 접수번호 | 접수시각 | 업체명 | 처리결과 | 담당자 |

|---|---|---|---|---|

| 3905 | 2024-07-17 13:30:25 | (�****** | 처리완료 | 금강펌프 |

| 3853 | 2024-05-08 17:10:43 | 경********** | 처리완료 | 금강펌프 |

| 3622 | 2023-03-16 08:31:17 | 한********* | 처리완료 | 금강펌프 |

| 3610 | 2023-02-24 12:15:31 | (�****** | 처리완료 | 금강펌프 |

| 3595 | 2023-02-04 07:59:09 | 한*** | 처리완료 | 금강펌프 |

| 3532 | 2022-09-28 15:22:53 | 대*** | 처리완료 | 금강펌프 |

| 2405 | 2016-10-12 15:55:21 | 플*** | 처리완료 | 금강펌프 |

| 1544 | 2014-11-25 08:44:01 | 대******** | 처리완료 | 금강펌프 |